I. Introduction of Semiconductor Lasers

Semiconductor lasers are commonly known as laser diodes, because they use semiconductor materials as working materials, so they are called semiconductor lasers. Semiconductor laser is composed of fiber-coupled semiconductor laser module, beam-combining device, laser energy transmission cable, power supply system, control system and mechanical structure etc. It realizes laser output under the driving and monitoring of power supply system and control system. The common working substances of semiconductor lasers are GaAs, CdS, InP and ZnS etc. According to different working substances, there are three main excitation modes: electric injection, pumping and high energy electron beam excitation.

(1)The electric injection type semiconductor laser is generally made of a working material such as GaAS, CdS, InP, or ZnS as a main material to form a semiconductor junction type diode. When subjected to electrical injection, the current injected along the forward bias is applied to the working substance. thereby generating stimulated emission in the nodal plane region.

(2) Pump lasers are generally doped with the single crystal of germanium with holes as carriers (p-type semiconductor single crystal) or germanium with electrons as carriers (n-type semiconductor single crystal) as the working material .The laser generated by other lasers is used as a pump excitation to achieve population inversion.

(3) High energy electron beam excited semiconductor lasers are generally similar to pump type lasers in the choice of working materials, and also choose semiconductor germanium single crystal. However, it is worth noting that high-energy electron beam-excited semiconductor lasers are mainly composed of PbS, CbS and ZnO in the selection of P-type semiconductor single crystals.

There are many kinds of semiconductor lasers. According to their chip parameters and packaging methods, there are many kinds of classification methods. Among them, the classification of semiconductor lasers for optical fiber output mainly includes the following:

Figure 1 Classification of Semiconductor Lasers:

II. Development of Semiconductor Laser Technology

Since the invention of the world's first semiconductor laser in 1962, great changes have taken place in semiconductor lasers, which has greatly promoted the development of other science and technology.

In recent years, the development of low power semiconductor lasers used in the field of information technology is very fast. For example, DFB for optical fiber communication and dynamic single-mode laser diodes, as well as visible light wavelength laser diodes widely used in optical disk processing, and even ultra-short pulse laser diodes have been greatly innovative progress.

The low power laser diode itself has this high integration, high rate, and tunable development characteristic. The development speed of large high power semiconductor lasers is also accelerating.

In the 1980s, the output power of independent laser diodes was over 100 mW, and the conversion efficiency reached 39%. By the 1990s, Americans had once again raised the index to a new level, reaching 45% conversion efficiency. In terms of output power, they had also changed from W to KW.

With the support of research and development projects in various countries, semiconductor laser chip structure, epitaxy growth, device packaging and other laser technologies have made considerable progress, and the performance of unit devices has also achieved major breakthroughs: electro-optic conversion efficiency of more than 70%, very low beam divergence angle, single bar continuous output power exceeding kilowatts. Using carbon nano (CN) heat sink, the cooling efficiency of the laser can be increased by 30% compared with the traditional semiconductor bar installation technology. The output power of 100 μm strip width single transistor reaches 24.6W, and the continuous working life of high power is tens of thousands of hours.

High-efficiency and high-power semiconductor lasers have also rapidly developed into all-solid-state lasers, which has provided LDP solid-state lasers with new opportunities and prospects for development.

III. Market Scale of Semiconductor Lasers

Semiconductor lasers have many advantages, such as small size, light weight, long life, high reliability of operation , low energy consumption, high electro-optic conversion efficiency, easy mass production and low cost etc. They are widely used in CD laser recorders, optical fiber communications, optical memory, laser printers and so on. They cover the whole field of optoelectronics.

With the continuous development and breakthroughs of technology, semiconductor lasers are developing towards shorter emission wavelength, larger emission power, ultra-small size and long life to meet the needs of various applications, and the products are becoming more and more abundant. It has also been widely used in laser processing, 3D printing, lidar, laser ranging, military, medical and life sciences etc. In addition, high power direct semiconductor lasers are widely used in cutting and welding fields by coupling them into optical fibers for transmission.

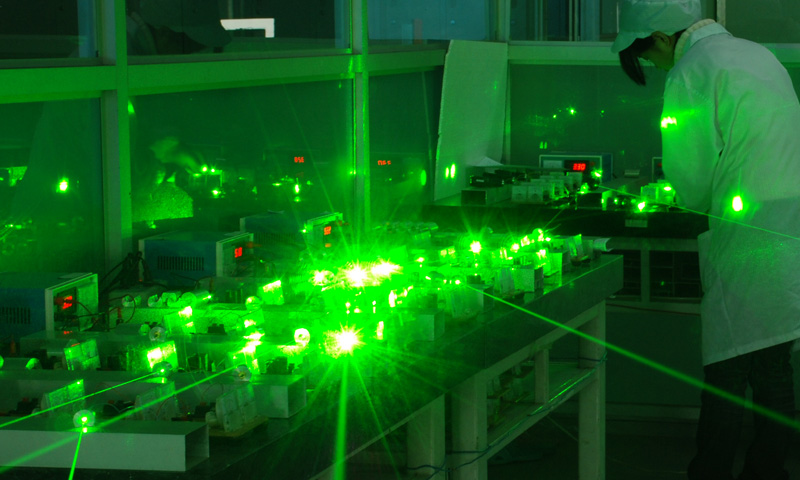

At present, the global semiconductor laser market is large, increasing from $3.54 billion in 2012 to $5.31 billion in 2017, with an annual compound growth rate of 8.4%.

Figure 2 Global semiconductor laser market size and growth rate in 2012-2017 (US$):

IV. Application of Semiconductor Lasers

1. Application of Semiconductor Lasers in the Field of Optoelectronics

(1) Optical fiber communication. Semiconductor laser is the only practical light source of optical fiber communication system, and optical fiber communication has become the mainstream of contemporary communication technology.

(2) CD Access. Semiconductor lasers (LDs) have been used in optical disk memory (CD-ROM). The greatest advantage of LDs is the large amount of sound, text and image information stored. Using blue and green laser can greatly improve the storage density of CD.

(3) Spectral analysis. Far-infrared tunable semiconductor lasers have been used for environmental gas analysis, monitoring air pollution, automobile exhaust and so on. It can be used to monitor the process of gas deposition in industry.

(4) Optical information processing. Semiconductor lasers have been used in optical information systems. Two-dimensional array of surface emitting semiconductor lasers (SELDs) is an ideal light source for optical parallel processing systems, which will be used in computers and optical neural networks.

(5) Laser microfabrication. With the help of Q-switched semiconductor lasers, high-energy ultra-short optical impulse can cut and punch integrated circuits.

(6) Laser alarm. Semiconductor laser alarm has a wide range of applications, including anti-theft alarm, water level alarm, car distance alarm and so on.

(7) Laser printer. High power semiconductor lasers have been used in laser printers. Using blue and green laser can greatly improve the printing speed and resolution.

(8) Laser barcode scanner. Semiconductor laser barcode scanner has been widely used in the sale of commodities, as well as the management of books and archive

(9) High definition laser TV. In the near future, semiconductor laser televisions without cathode ray tubes can be put on the market. It uses red, blue and green lasers and estimates that their power consumption is 20% lower than existing televisions.

2. Application of Semiconductor Laser in Material Processing

Semiconductor lasers are mostly used in material cutting and circuit board processing. Because of the high stability and efficiency of the laser, it can easily cut industrial materials accurately, and in the processing of high-frequency circuit board, low-wavelength ultraviolet laser also has a good application.

(1) Pumping Source of Fiber Laser and Solid State Laser

At present, the most important application of semiconductor lasers is as pumping source of fiber lasers and solid-state lasers.As a pumping source of fiber laser, improving the unit power of semiconductor lasers can fundamentally simplify the structure of pumping system or improve the level of pumping power. With the increasing output power of fiber laser and solid-state laser, the power of semiconductor pumping source is also put forward higher requirements.

(2) Metal Cutting

Due to the limitation of beam quality, it is difficult for traditional semiconductor lasers to be directly used in metal cutting. In recent years, with the improvement of semiconductor coupling technology and the gradual maturity of new beam combining technology, some semiconductor lasers with the output of optical fibers above kilowatt level can meet the requirements of beam quality for cutting. In addition, due to the diversity of the wavelength of semiconductor lasers, the wavelength of short-wavelength semiconductor lasers is very close to the maximum wavelength absorption of aluminum. In the automotive industry, high-power semiconductor lasers are very suitable for the welding of aluminum body. Semiconductor lasers with output power of 2 KW to 6 KW have been widely used in automobile industry.

(3) Plastic Welding

Laser welding using small and medium power semiconductor lasers improves the traditional method of thermoplastic welding. For example, by means of ultrasonic welding, the connecting area can be directly plasticized before compaction. Laser can realize laser welding of light penetration type, form uniform melt in the connecting area, and avoid bristling caused by friction. Semiconductor laser plastic welding is widely used in sealing welding of sensors or plastic boxes in automotive industry. It can also be used in edge-wrapping of wood products or in processing synthetic materials reinforced by fibers.

(4) Laser Cladding

Laser cladding, also known as laser cladding or laser cladding, is a surface modification technology. By adding cladding materials on the surface of the substrate and using high energy density laser beam to make it solidify with the thin layer on the surface of the substrate, a cladding layer with metallurgical bond is formed on the surface of the substrate. Semiconductor lasers can be used in cladding process to reduce the mixing of powder and collective materials and less heat input, further improving the economic benefits of cladding process.

(5) Laser Tin Welding

Tin soldering is a kind of welding method that uses low melting point metal solder to heat and melt, infiltrates and fills the gap between the joints of metal parts. The solder is usually tin-based alloy. At present, semiconductor lasers with output power of 100W have been widely used in tin welding. With the further reduction of the price of semiconductor lasers, the continuous improvement of labor costs and the advancement of intelligent manufacturing and precision manufacturing, it is expected that laser tin welding will gradually replace the traditional soldering iron welding and be widely used in the future.

3. Military Applications of Semiconductor Lasers

Low power semiconductor lasers are widely used in laser guidance and ranging because of their small size, long lifetime and easy modulation. Simple and easy, and achieved good results. Now the development of high-power semiconductor lasers has also made them brilliant in the military field, lidar and laser simulation, as well as deep-sea optical communication, have been greatly developed.

The military applications of semiconductor lasers include: pumping source of high-energy laser weapons, high power semiconductor laser beam combination is applied directly; laser guidance, which enables missiles to fly in the laser beam until destroying the target; semiconductor laser guidance is mostly used for ground-to-air missiles, air-to-air missiles, ground-to-ground missiles, etc;laser ranging, mainly used in anti-tank weapons as well as aviation, aerospace and other fields; lidar, used for monitoring targets, precise positioning of incoming targets and terrain tracking of helicopters and cruise missiles. The applications of guidance and ranging are mainly high-power pulsed semiconductor lasers, whose wavelength is concentrated near 904 nm. In recent years, based on human eye safety considerations, they have developed towards long wavelength.